Clean room anti static coat work suit

Brand Huaxin,OEM

Product origin Xianning Hubei China

Delivery time 30days

Supply capacity 1000pcs/day

Applications: This ESD electrial protection coat can be apply to Electronics Manufacturing and Assembly,Pharmaceutical and Biotechnology Industries,Explosive and Hazardous Environments,Aerospace Industry,Healthcare and Medical Device Manufacturing,Data Centers and IT Facilities,Automotive Industry,Printing and Packaging Industries.

Features & Benefits: This ESD electrial protection coat with carbon fiber has strong barrir of anti-static, This polyester material with carbon will not be only durable, it also has strong static resistant, it will protect people safe and also protect your electronic equipment from damage,case by the static from human body. Meanwhile the optimized body fit supply improved wearer comfort and safety.

Fabric feature: The lightweight soft polyster fabric will supply improved wearing experience. While it has strong resistant of static. to protect people from static harzards.

Clean room anti static coat work suit

Place of Origin: Xianning,Hubei, China (Mainland)

Brand Name: OEM, Huaxin

Model Number: HX-ASC

Material: 99.5% Polyester+0.5% carbon fiber thread

Color: Blue, pink,etc.

Weight: 120gsm, etc.

Size: S,M,L,XL,2XL

Sewing: Stitched seam

Style: With hood, elastic wrist/ankle, Elasticated waist, zipper front, with pockets

Package: 1pc/bag, 50pcs per carton/pack

Garment features: antistatic, comfortable, lightweight, dust proof

Applications:

1. Electronics Manufacturing and Assembly

Purpose: Prevent static discharge that could damage sensitive electronic components such as microchips, circuit boards, and semiconductors.

Environment: Cleanrooms, electronics assembly lines, and testing facilities.

Importance: Static electricity can cause irreversible damage to electronic components, leading to costly failures.

2. Pharmaceutical and Biotechnology Industries

Purpose: Avoid static interference with sensitive laboratory equipment and prevent contamination of products.

Environment: Laboratories, cleanrooms, and production facilities.

Importance: Static can attract dust and particles, compromising the sterility of pharmaceutical products.

3. Explosive and Hazardous Environments

Purpose: Prevent static sparks that could ignite flammable gases, vapors, or dust.

Environment: Chemical plants, oil refineries, grain elevators, and fireworks manufacturing.

Importance: Static discharge can trigger explosions or fires in environments with flammable materials.

4. Aerospace Industry

Purpose: Protect sensitive aerospace components and systems from static damage during assembly and maintenance.

Environment: Aircraft assembly hangars, maintenance facilities, and testing labs.

Importance: Static can interfere with avionics and other critical systems.

5. Healthcare and Medical Device Manufacturing

Purpose: Prevent static interference with medical devices and ensure a sterile environment.

Environment: Hospitals, medical device manufacturing facilities, and research labs.

Importance: Static can affect the accuracy of medical equipment and compromise patient safety.

6. Data Centers and IT Facilities

Purpose: Protect servers, storage devices, and networking equipment from static discharge.

Environment: Server rooms, data centers, and IT maintenance areas.

Importance: Static can cause data loss or hardware failure in critical IT infrastructure.

7. Automotive Industry

Purpose: Prevent static damage to electronic components in vehicles during manufacturing and assembly.

Environment: Automotive assembly lines and testing facilities.

Importance: Modern vehicles rely heavily on electronics, which are vulnerable to static discharge.

8. Printing and Packaging Industries

Purpose: Avoid static buildup that can attract dust or cause misfeeds in printing and packaging machinery.

Environment: Printing presses, packaging lines, and material handling areas.

Importance: Static can disrupt production processes and reduce product quality.

Lead-time: 30-60 days

Payment terms: T/T

Minimum order quantity: 1000pcs

FOB Port: Shanghai/Wuhan

Key words about our factory:

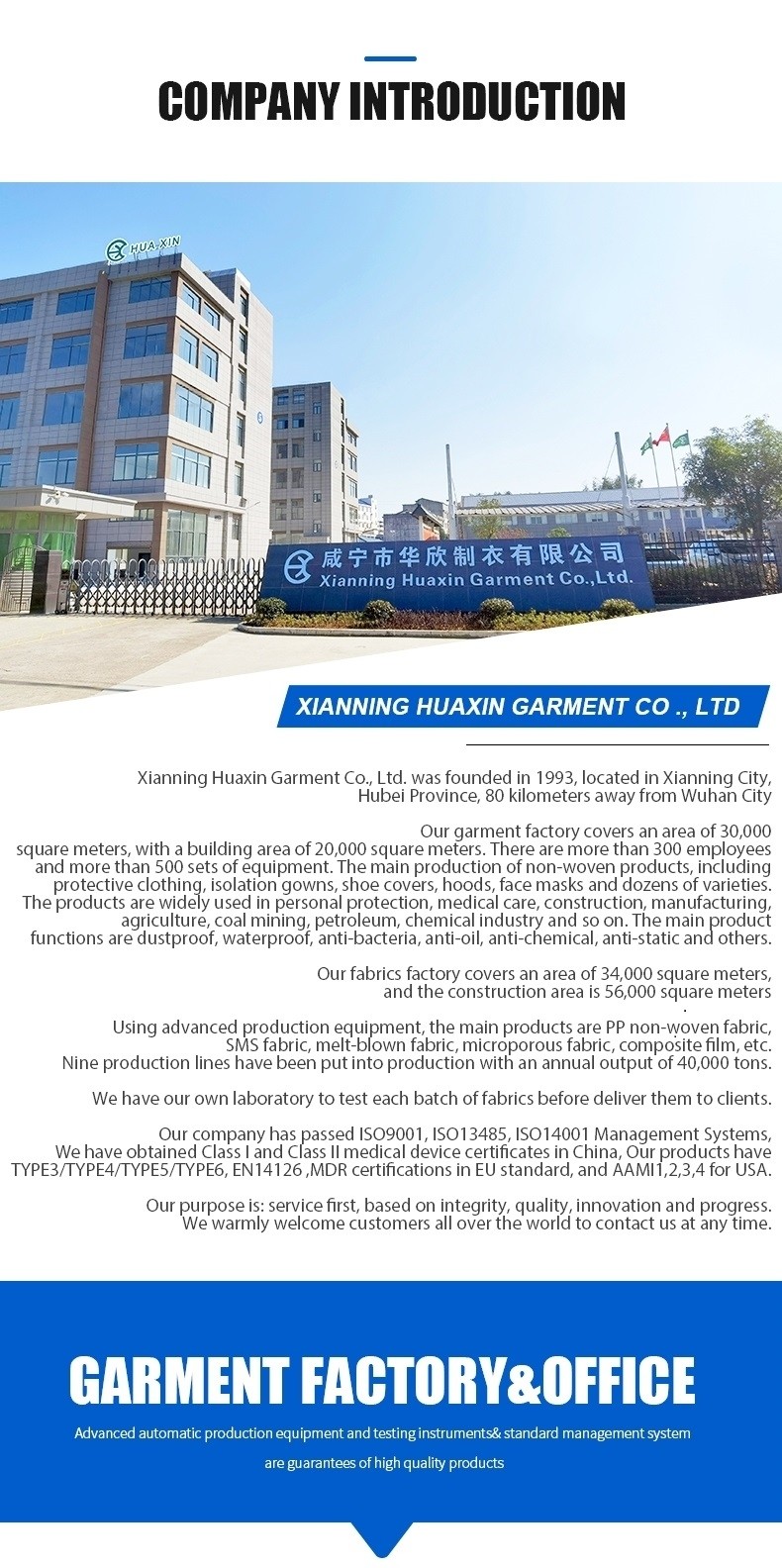

1993--We established in 1993,we have history of 31 years

300+--We have more than 300 skillful & professional workers, and they are stable

500+--We have more than 500 advanced equipment

26000+--We cover more than 26000 square meters

CE certifications--Our products have CE certifications TYPE3B TYPE4B TYPE5B TYPE6B and MDR,

EN13795 etc.

ISO Management Systems--Our company run under Management Systems of ISO9001, ISO14001,

ISO13485